We are open Monday to Friday

Product Hotline - 01993 704 981

Local call rate - 0208 0909586

Studio Wall Technical Specification

Acoustic Mineral Wool

General Physical Data

| Flammability: | BS 476 Part 4 (1970) Non-combustible |

| Building Regulations: | Class O |

In some situations, there is a requirement for party/compartment floors to achieve a one-hour fire rating. If AMW100 is supported by 25mm chicken wire mesh stapled to joist sides, the insulation will then provide this one-hour fire rating.

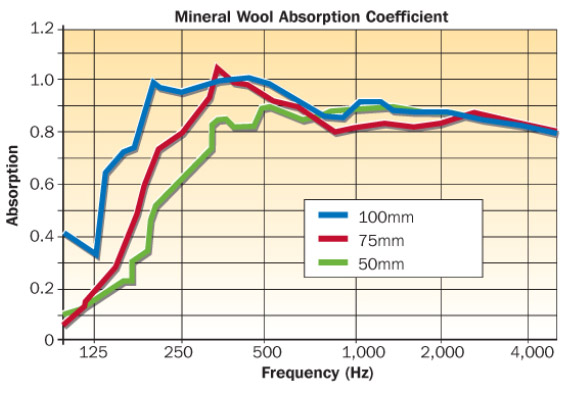

Acoustic Performance AMW typically provides a reduction in reverberant noise levels of up to 10dB when fitted under roof constructions Sound Absorption coefficients.

The graph below shows typical sound reduction obtainable under test conditions

Sound Reduction Obtainable

| Thermal Conductivity W/mK | Mean Temperature ˚C | ||

| AMW50 | 0.038 | ||

| AMW100 | 0.049 | ||

| R Value (m2K/W Value | |||

| AMW50: | 1.40 | ||

| AMW100 | 2.85 | ||

Soundproofing Mat

General Physical Data

| Colour: | Dark Grey to black |

| Supply Form: | Available in sheet form |

| Sheet Size: | nom. 1200 x 1200mm (4ft x 4ft) |

| Nominal Thickness: | 2mm +/- 0.6mm |

| Piece Density: | 5kg/m2 +/- 10% |

| Service Temperatures – (Securely fixed) <90oC for extended periods <120oC for short periods> | |

| Flammability: | FMVSS 302 self-extinguishing |

| Shelf Life: | Indefinitely in cool, dark storage conditions |

Special Spray Adhesive

See the Health & Safety Data sheet HERE

Acoustic Sealant

Technical Data

. Properties Values

| Application temperature | +5°C to +40°C | ||

| Service temperature | -10°C to +70°C | ||

| Skinning time @ 20°C/65%RH | 5 minutes | ||

| Cure rate | Time to full cure is dependent on sealant depth, ambient temperature and humidity. | ||

| Chemical resistance | Fair resistance to most alkalis and dilute acids; poor resistance to hydrocarbon solvents. | ||

| UV resistance | Not applicable | ||

| Service life | 15 years + | ||

| Movement accommodation | Butt joints (movement in tension and compression): 10% Lap joints (movement in shear): 20% | ||

| Colours | White. | ||

Equipment

Mastic gun

Our Acoustic Sealant is a one-part Fire Retardant Water-based Acrylic Sealant. It exhibits good adhesion to a wide variety of common building substrates without the need for a primer. Paintable with emulsion paint three hours after application. Allow 12 hours before overpainting with gloss paints.

When subject to flame our sealant will intumesce (expand and char), thus blocking the passage of fire and smoke.

Specification Compliances

BS EN ISO 11600 F 7.5P

BS 476 Part 20: 1987

Warres Report No: 23282, 9th March 1995

Warres Report No: 116997, 20th February 2001

Warres Report No: 119344, 12th July 2001

Warres Report No: 123325/A, 27th March 2002

Application Instructions

Joint Preparation

The joint surfaces must be clean, dry and free from all contamination. The surfaces should be degreased using a suitable cleaner.

Joint Backing

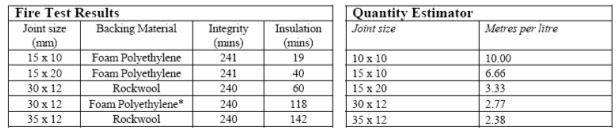

Where applicable, appropriate joint filler e.g. our AMW or closed cell polyethylene foam, should be used to provide the correct joint depth (see chart under Technical Data for fire integrity and insulation achieved).

Application

Our sealant is supplied in cartridges and can be applied into the joint using a Caulking Gun. All joint preparation, priming, and sealant application should be carried out in accordance with BS8000 Part 16, the British Standard for the sealing of joints in buildings using sealants.

Joint Size suitability

Joint Width

Minimum 6mm

Maximum 20mm (single application)

Joint Depth

Minimum 10mm on porous substrates

Minimum 10mm on non-porous substrates

Maximum 20mm

Width :Depth ratio (within above min/max restrictions)

Contact Technical Services. In general, joints should be as narrow as possible to prevent passage of fire.

Storage Life

12 months in original unopened package stored in a cool, dry place out of direct sunlight.

Health & Safety for Acoustic Sealant

Avoid prolonged contact with the skin. If sealant cones into contact the eyes, flush with copious volumes of cold water and obtain medical attention. For further information consult Product Safety Data Sheet.

*Test incorporates seals and backing material on both faces of the construction.

Packaging: Polyethylene nozzles are included with each tube. Important: The information in this leaflet is given in good faith and based on results gained from experience and tests. However, all recommendations or suggestions are made without guarantee since the conditions of use are beyond our control. Goods are supplied subject to the Company’s terms and conditions of sales.

Acoustic Plasterboard – Health & Safety Data Sheet

1. Composition/Information on ingredients

Plasterboard and cove comprise in general of a core of calcium sulphate dihydrate encased in paper liners. Minor additives include starch, foaming agents and dispersants. Moisture resistant boards and core board contain a silicone additive.

Fire resistant boards and core board include small quantities of glass fibre and vermiculite.

Foil-Backed boards are backed with a metalised polyester film.

2. Hazards Identification

Cutting and sanding of plasterboard or cove may generate excessive dust.

Gypsum dust may irritate eyes or sensitive skin, it may irritate the respiratory system.

It is better for the operator to wear non-restrictive clothing, especially avoiding constrictions at neck and wrist etc. It is recommended that work clothing should be washed and company separately from other family clothing.

3. First Aid Measures

Inhalation: Remove the person to fresh air.

Skin contact: Rinse skin with running water, then wash with water and soap.

Eye contact: Irrigate with plenty of water and obtain medical advice.

Ingestion: Wash mouth out and drink plenty of water.

Please note: should any symptoms persist obtain medical assistance.

4. Fire-fighting Measures

Plasterboard and cove have a limited combustibility.

5. Accidental release measures

The formation of dust should be controlled and suppressed, collect released dust and put into bags.

Prevent these products from contaminating drains and watercourses.

(refer to section 8, Exposure/Protection and section 13.

Disposal Considerations).

6. Handling and Storage

Plasterboards are supplied shrink wrapped on timber bearers. Packs should be lifted with a fork lift truck, the forks being set so there is an even weight distribution and no deformation of the pack. Ensure

handling equipment is of adequate capacity and that the personnel are advised of handling procedures and safety clothing. Care should be taken at all times to avoid strain to the handlers. Boards should not be lifted at the short edges or carried horizontally. Carry the boards on the edge, two persons per board by supporting one long edge and gripping upper edge to avoid breaking due to flexing.

Plasterboards must be stored flat in a clean dry environment on a flat surface. If timber bearers are used to

store boards on site, they should be a minimum 40mm wide and placed at a maximum 450mm centres.

Note: If handling manually, consider risks as required by manual handling operations regulations 1992.

Plasterboard are not designed to support body weight; fixers must work from an independent support

system.

7. Exposure controls/personal protection

Occupational exposure limits

| Substance | Total inhalable | Total respirable |

| Gypsum | 10mg/m³ | 4mg/m³ |

| Limestone | 10mg/m³ | 4mg/m³ |

| Quartz | 0.3 mg/m³ | (MEL) |

| MMMF | 5 mg/m³ | (MEL) |

Note: 8 hour TWA reference period

The man made mineral fibres (MMMF) used in our Acoustic Plasterboard.

Personal protection

Respiratory: The area of work requires appropriate ventilation and dust formation should be minimised and controlled. If dust formation can not be controlled wear a half face mask to EN 149 Class FFP1S.

Hand: Protective gloves can be worn, a barrier of cream can be applied to the hands to reduce the effect of hand contact.

Eye: If the formation of dust is likely to occur, safety goggles to BS EN 166 2A5 are recommended.

Skin: To avoid skin contact wear overalls and footwear.

8. Physical and chemical properties

Appearance: Plasterboard is a sold flat sheet in a paper envelope.

Colour: Varies depending on type.

pH: 7 (Neutral)

(Refer to section 1 Composition/Information on ingredients)

9. Stability and reactivity

Stable and unreactive.

10. Toxicological information

Inhalation: Dust can cause short term irritation to the respiratory system, no known long term effects.

Skin contact: Prolonged or repeated contact may cause dry skin leading to irritation.

Eye contact: Short term irritation can be experienced due to dust formation.

Ingestion: Wash mouth out and drink plenty of water.

11. Ecological information

Not applicable.

12. Disposal Considerations

Can be disposed of at an authorised landfill site in accordance with local or national regulations.

13. Transport Information

Not classified as hazardous for transport.

14. Regulatory Information

Products are not classified as hazardous under:

Occupational Exposure Limits EH40, (reviewed and Personal protection reprinted annually).

Control of Substances Hazardous to Health (COSHH) Regulations 2002.

15. Other Information

This product should be used as directed by Sound Service (Oxford) Ltd. For further information consult the technical department.

An on-site risk assessment should be carried out before use.

This safety data sheet:

• Supersedes all previous issues, and users are cautioned to ensure it is current. Destroy all previous

data sheets, and if in any doubt, contact Sound Service, quoting the date in the top right hand corner of this document.

•Does not replace the users own workplace risk assessment.

•Was compiled using the current safety information supplied by the distributors of the component

materials.

•Is based on the present state of our knowledge and is intended to describe out products from the point of

view of health and safety requirement. It should not be construed as guaranteeing specific properties.