We are open Monday to Friday

Product Hotline - 01993 704 981

Local call rate - 0208 0909586

Bronze Floor Cavity System Technical Specification

Soundblocker Membrane

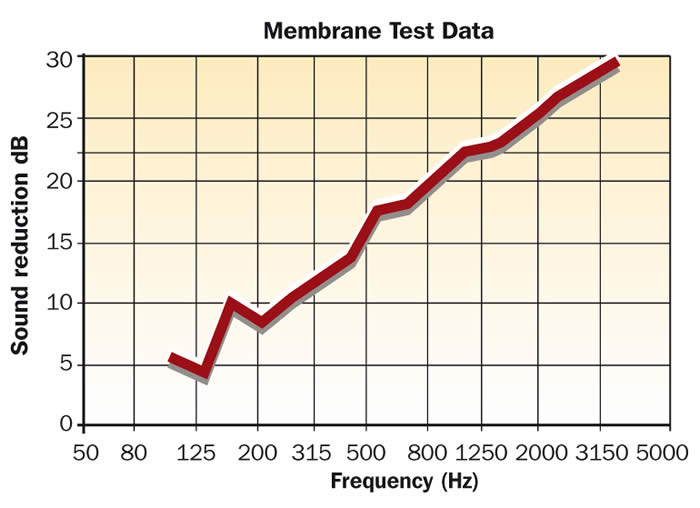

The membrane Complies with BSEN ISO 140.

Acoustic Mineral Wool

General Physical Data

| Flammability: | BS 476 Part 4 (1970) Non-combustible |

| Building Regulations: | Class O |

In some situations, there is a requirement for party/compartment floors to achieve a one-hour fire rating. If AMW100 is supported by 25mm chicken wire mesh stapled to joist sides, the insulation will then provide this one-hour fire rating.

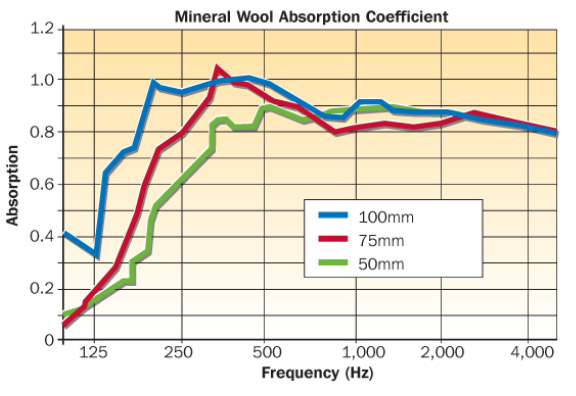

Acoustic Performance AMW typically provides a reduction in reverberant noise levels of up to 10dB when fitted under roof constructions Sound Absorption coefficients.

The graph below shows typical sound reduction obtainable under test conditions

Sound Reduction Obtainable

| Thermal Conductivity W/mK | Mean Temperature ˚C | ||

| AMW50 | 0.038 | ||

| AMW100 | 0.049 | ||

| R Value (m2K/W Value | |||

| AMW50: | 1.40 | ||

| AMW100 | 2.85 | ||

Acoustic Sealant

Technical Data

. Properties Values

| Application temperature | +5°C to +40°C | ||

| Service temperature | -10°C to +70°C | ||

| Skinning time @ 20°C/65%RH | 5 minutes | ||

| Cure rate | Time to full cure is dependent on sealant depth, ambient temperature and humidity. | ||

| Chemical resistance | Fair resistance to most alkalis and dilute acids; poor resistance to hydrocarbon solvents. | ||

| UV resistance | Not applicable | ||

| Service life | 15 years + | ||

| Movement accommodation | Butt joints (movement in tension and compression): 10% Lap joints (movement in shear): 20% | ||

| Colours | White. | ||

Equipment

Mastic gun or Click n Seal gun

Our Acoustic Sealant is a one-part Fire Retardant Water-based Acrylic Sealant. It exhibits good adhesion to a wide variety of common building substrates without the need for a primer. Paintable with emulsion paint three hours after application. Allow 12 hours before overpainting with gloss paints.

When subject to flame our sealant will intumesce (expand and char), thus blocking the passage of fire and smoke.

Specification Compliances

BS EN ISO 11600 F 7.5P

BS 476 Part 20: 1987

Warres Report No: 23282, 9th March 1995

Warres Report No: 116997, 20th February 2001

Warres Report No: 119344, 12th July 2001

Warres Report No: 123325/A, 27th March 2002

Application Instructions

Joint preparation

The joint surfaces must be clean, dry and free from all contamination. The surfaces should be degreased using a suitable cleaner.

Joint Backing

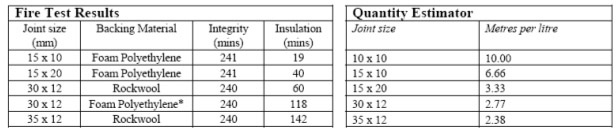

Where applicable, appropriate joint filler e.g. our AMW or closed cell polyethylene foam, should be used to provide the correct joint depth (see chart under Technical Data for fire integrity and insulation achieved).

Application

Our sealant is supplied in cartridges and can be applied into the joint using a Caulking Gun. All joint preparation, priming, and sealant application should be carried out in accordance with BS8000 Part 16, the British Standard for the sealing of joints in buildings using sealants.

Joint Size suitability

Joint width

Minimum 6mm

Maximum 20mm (single application)

Joint Depth

Minimum 10mm on porous substrates

Minimum 10mm on non-porous substrates

Maximum 20mm

Width :Depth ratio (within above min/max restrictions)

Contact Technical Services. In general, joints should be as narrow as possible to prevent passage of fire.

Storage Life

12 months in original unopened package stored in a cool, dry place out of direct sunlight.

Health & Safety for Acoustic sealant

Avoid prolonged contact with the skin. If sealant cones into contact the eyes, flush with copious volumes of cold water and obtain medical attention. For further information consult Product Safety Data Sheet.

*Test incorporates seals and backing material on both faces of the construction.

Packaging: Polyethylene nozzles are included with each tube. Important: The information in this leaflet is given in good faith and based on results gained from experience and tests. However, all recommendations or suggestions are made without guarantee since the conditions of use are beyond our control. Goods are supplied subject to the Company’s terms and conditions of sales.