We are open Monday to Friday

Product Hotline - 01993 704 981

Local call rate - 0208 0909586

Tecsound T50 Installation Guide

A PDF version of this page can be downloaded HERE

T50 and T50S rolls are very heavy products and help will be required when handling!

Because this soundproofing material is produced using a large percentage of recycled materials, there may sometimes be a ‘distinctive’ smell when the product is first unpacked. Usually any smell will abate within a few days but as a precaution, we advise applying a thin layer of polythene over the insulation on walls and floors before the final covering is installed to seal in any possible smells.

INSTALLATION FOR soundproofing of FLOORS

First ensure the perimeter of the floor is sealed against the wall or skirting by sealing with our Acoustic Sealant.

Then ensure that all floorboards are securely fixed with no protruding mechanical fixings that can damage the sound insulation. If the floor squeaks when walked on then tighten it up with strategically placed screws until all squeaking has been cured.

A sharp knife or large scissors will now be required for trimming the T50.

Install the T50 with the scrim side down wall to wall ensuring it is tightly butted to the room perimeter with no unnecessary gaps. If gaps do appear then seal them with Acoustic Sealant.

For best results, several layers will be required so install with the joints tightly butted to one another which each subsequent layer overlapping the joints of the former.

If a carpet is being fitted on top, carpet grippers can still be used as normal but longer fixings may be required depending on the number of layers being installed.

It is advisable to tape all of the joints so that they remain tightly butted and do not separate. Separation will severely reduce the soundproofing properties of the product.

INSTALLATION FOR soundproofing of STUD WALLS

It is best to use the T50S for these because being self-adhesive, eliminates the need for solvent based separate adhesives.

For best results the following instructions should be applied to lightweight stud walls and the installation proceeds as follows.

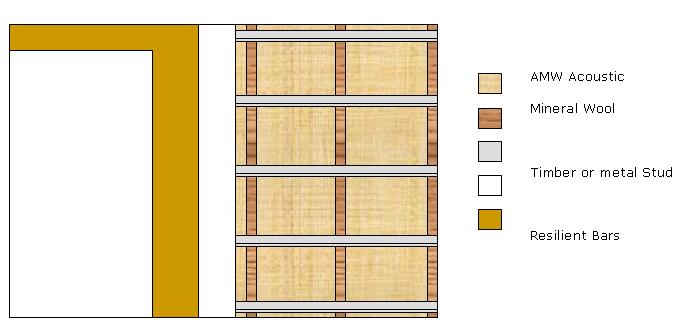

TECSOUND SOUNDPROOFED STUDWALL SIDE ON VIEW

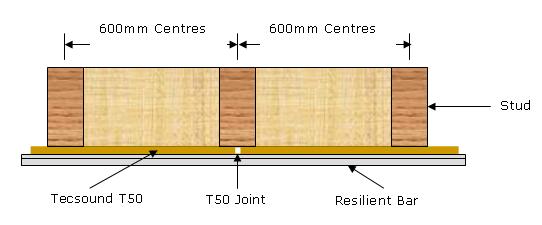

TECSOUND SOUNDPROOFED STUDWALL TOP DOWN VIEW

Measure the height of the wall carefully then cut the correct length from a roll of T50S. Two people will make the operation easier from hereon. Peel back a few inches of the release paper from the back of the soundproofing mat then carefully offer it up to the top of the wall where it meets the ceiling ensuring that it is perfectly aligned. Firmly adhere the product to the wall then gradually peeling off the release paper, fix the mat to the wall making sure there is no creasing or knifing of the mat and continue in this way until all of the mat has been securely fixed to the wall. If any bubbles are apparent then pierce the bubble with a knife and press the bubble flat allowing the air to escape through the small hole.

Repeat this operation along the entire wall until the entire surface has effectively been covered. If there any gaps between the joints then seal with Acoustic Sealant. Now high density Acoustic Plasterboard can be used as the covering layer on top of the T50S and can be screwed through to the supporting frame.

For even better results, our T50 scrim backed soundproofing mat can be stapled to the stud frame after infilling with Acoustic Mineral Wool and prior to the fixing of resilient bars. If this is to be done it is important that the shiny side of the mat is fixed to the stud with the scrim side outermost. Simply staple the mat to the stud and overlap the joints by at least 50mm. When all of the stud has been covered screw on the resilient bars as normal and according to the resilient bar installation instructions. Then screw on the first layer of Acoustic Plasterboard and proceed according to the instructions given previously.

If you should forget to include a polythene sealing layer when this product is sandwiched between two layers of Acoustic Plasterboard and a smell is evident, you can overpaint with a primer sealer that has been tried and tested by another customer.